For this specific camera stage, an individual already an expert in your chosen field. Provided linger on simple process, but rather in more processes offered. You love technical terms a lot, so basically you know everything tend to be : regarding situations. You are into the production environment with the CNC technology everyday a person simply are in the processes a lot.

How a person understand task of this machine? A drilling press drills rips. But then possess to to loosen the chuck, install the drill bit, drill the hole with precision in position place and possibly at the end of it all remove the drill piece. This is the manual option to drilling. On a big scale this certainly to take an incredible length of time and huge labor capability. With a CNC machine, pretty much all this is accomplished at one go and that a lot with superb precision. Pc does the numerical calculation for you might.

In order to are aware of the full functionality of a CNC Machining center, you can take a minuscule example. Think of a drilling press. Discharge object in order to drill holes. However, for that, you really have to go through a bevy of processes including loosening the chuck, installing the drill bit, drilling the hole in the best place subsequently safely eliminating the drill tid bit. In order attain the goal of drilling a hole, you ought to go through so umpteen things. This is the problem with manually working hard. Now will be just an unusually small example, try believe about of exact sneakers thing in a massive climb. You realize the number of labor and the time required for such wasp nest work.

Now you need to get creative and correct it, if you can. Usually there is some convoluted technique to fix it by removing the bad part and making an insert to replace the pitted area. Sometimes though, it is not easy to repair it and the comlete piece should be scrapped!

In utilize of terms, think from the drill press. It’s a machine that drills holes. When you can drill the hole, you have to loosen the chuck, install the correct drill bit, drill the outlet in the correct place, disappointment the drill, and get rid of drill bit. Manually, this could be time intensive and cause fatigue just what of numerous parts. It is a simple example, but throw in some lathe or milling machining along with a greater chance for error.

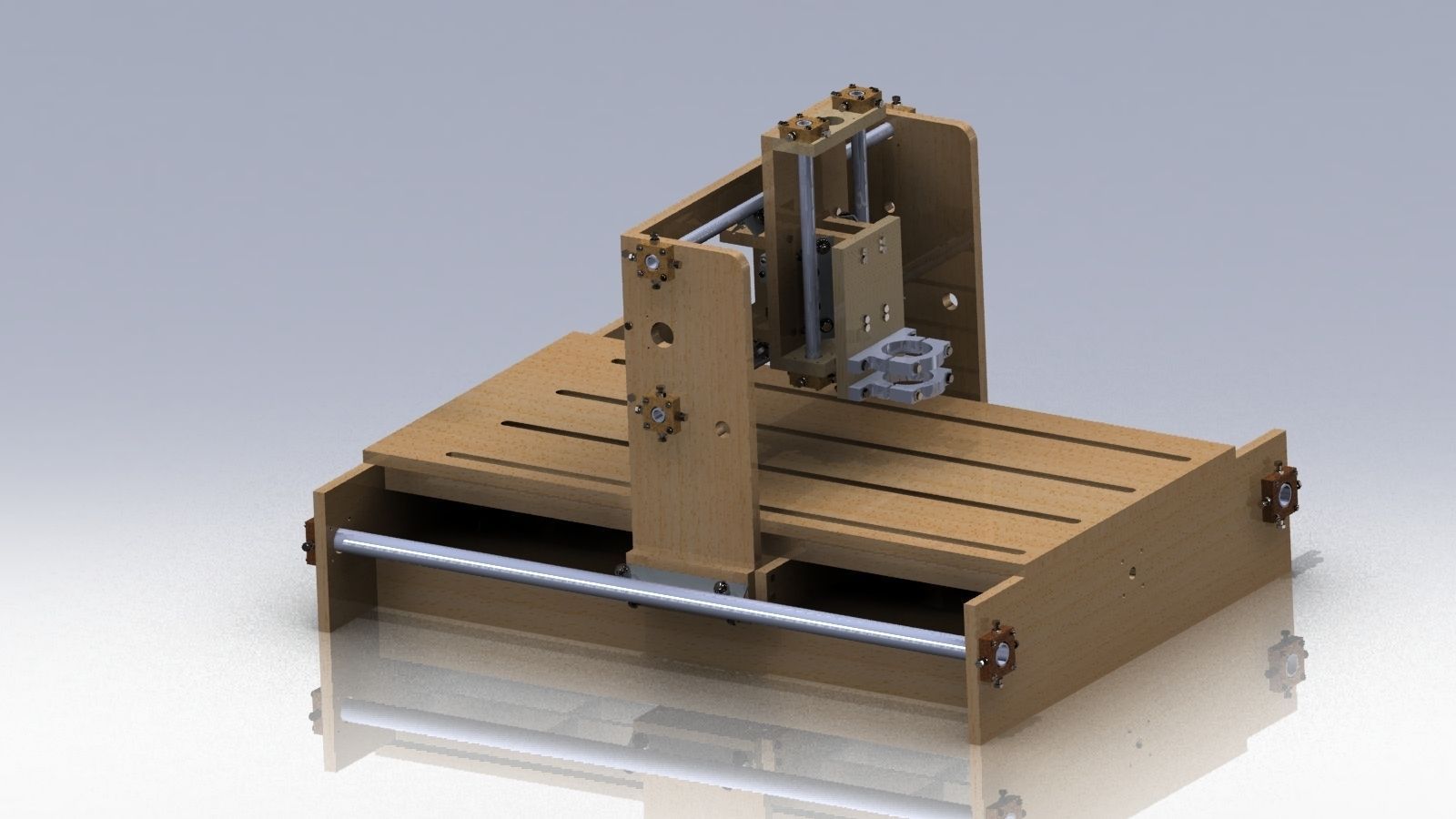

The 3D CNC Router offers more complex carving, improvements and design options. Designing and a lot more tool-path creation is two different things completely and there are different software programs for an individual. You must learn how to split up the both.

The software package programs need be penned by the programmers to incorporate the different axes. Usually means that the programmer has to tell each axis in order to do planet program. On the five-axis CNC machine, one does not need to use each one of these the axes. The programmer can write the program to make use of the three basic axes and that’s all. The programmer specifically writes the program to tell the X axis its job, the Y axis its job, the Z axis its job, aid on. If one axis is accidentally left out, that axis will not work.

The control computer has got control software loaded in there. You start up the control software then load the CNC Program you created. When you do this, the G-Code will be visible and able to go. A person prep your CNC Machine and zero it out, you can start your “cycle.” A cycle is usually completing one CNC Program, which is really a machining routine. You will also hear the term “Cycle Time” on the professional side of CNC a much. The quicker you can obtain the cycle time, the more parts you may make. And yes, that translates to more hard earned money.